Step 1: Get the Old Batteries Out

The House batteries in our Selene 60 are in an almost ideal place. They are in the bilges of the master and center staterooms. The bilges in the Selene 60 are nearly 3 feet deep, which is one of the things I really liked about the design. Having the house batteries in that space means that they are out of the hot engine room, they are low in the boat, and they are not taking up valuable space in the lazarette.

The only down-side to their location is that it's not particularly easy to get them our....or new ones in. This is the single biggest factor in my (now proving to be wise) decision to hire this out. I was tempted to think I could do it myself. I prefer to do most maintenance and improvement projects myself. But there are 24 125-pound batteries in the bilge. All but seven of them are relatively easily accessed through hatches in the floor of the master stateroom and center stateroom. However, seven of them on the starboard side of the main water tank under the master berth require a bit of a contortionist to get to. This is simply not a job for a 70-year old man with metal knees.... (see the photo in the first post in this series of one of the groups of batteries).

So....Dylan and Jarad Hildebrand are taking on this job, with Jarad doing the majority of the work. He's considerably bigger than I am, so I really wondered how he would do with getting to the hardest group of 7 batteries on the starboard side. I'm delighted to report that as of today (Friday....just two days after we left the boat in his hands), all of the batteries are out of the bilge!

Jarad has done a great job of putting down protection for the floors and the batteries are all "staged" the batteries to be moved aft through the engine room and out through the stern door in the lazarette.

Twenty four of these 125-pound beasts are being removed and we will replace them with just six Victron 300AH 25V batteries. Each of the Victron batteries is about the size of 5 of the original batteries, but each Victron battery weighs about the same as one of the original AGM batteries. So, we'll take out roughly 3,000 pounds of batteries and replace them with just over 700 pounds of new batteries---and still get nearly twice the useable capacity! I'm excited!

Update: Saturday November 29

We dropped the boat at Ladysmith on the afternoon of Tuesday, November 12. I spent a bit of time with Dylan and Jarad on Wednesday, the 13th, and we left to come back to our home in Gig Harbor that afternoon. Jarad has been making great progress and the work is about 80% complete. Actually placing the new batteries is one of the last steps because it's considerably easier to install all the wiring before the batteries are installed, while the space is a bit more open.

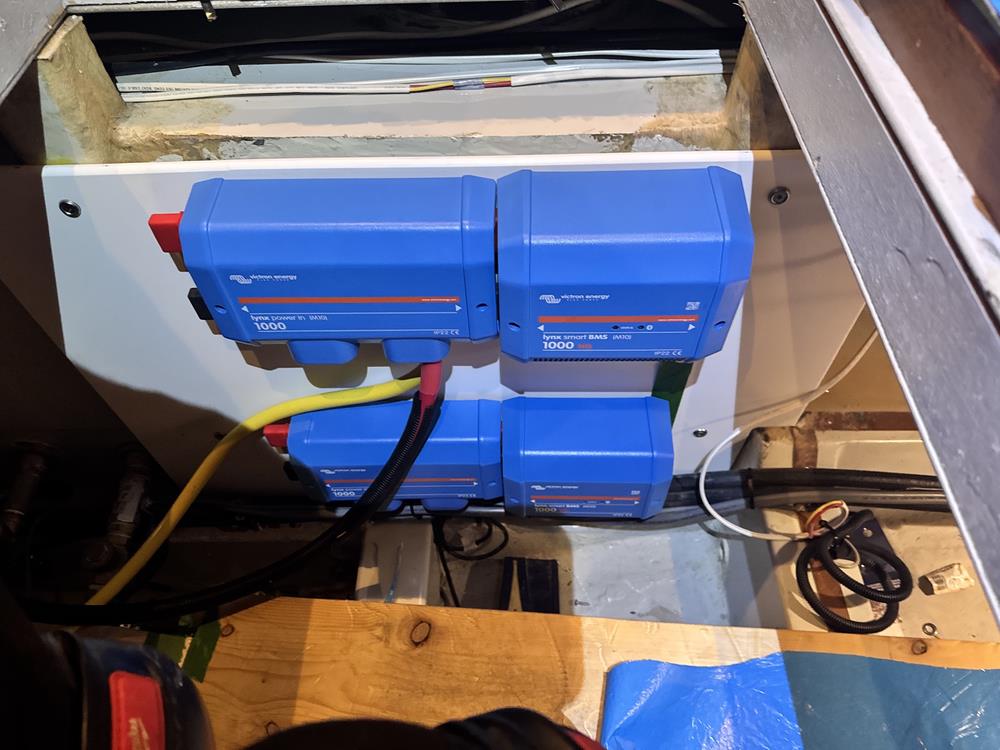

We're installing six 300AH batteries and have decided to install them in two "banks" of three batteries each. Each bank will be controlled and monitored by a separate Victron NG battery management system (BMS). This both reduces the amount of current through each BMS, but also provides some redundancy in case one of the BMSs fails. I like the setup. The BMSs are mounted in the bilge close to the batteries. I've attached a few photos. In the last photo, one of the new batteries is sitting in front of the generator--not installed yet. It's obvious they are quite long! Two of these batteries will sit side-by-side in a space that previously held about 5 of the old batteries. We plan to install them in the same locations in three pairs. We'll end up with one whole area up under the center stateroom that has no batteries because we just didn't need the room!